Products

-

Flexible polyurethane foam (commonly known as "sponge" or "foam rubber") is one of the most versatile open cell synthetic materials. Divided into two large families, polyether and polyester, and available as raw material in blocks or rolls, there are hundreds of types, which have different colours, physical-mechanical characteristics and behaviour in fire. There are numerous uses, depending on the type chosen.

-

Polyethylene foam is the name that polyethylene acquires when it is transformed through a chemical or physical foaming process. Polyethylene foam has a cellular structure, which makes it particularly light and suitable for use in the packaging sector and for thermo-acoustic insulation.

-

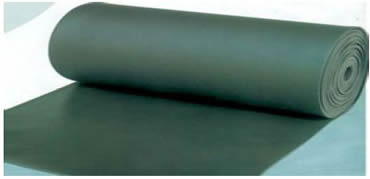

Elastomeric or nitrile rubber is a synthetic rubber obtained from the copolymerisation of acrylonitrile with butadiene. Though the physical and chemical properties vary depending on the composition of the copolymer, this form of synthetic rubber is generally resistant to oil, mineral fats, hydraulic fluids coming from petroleum, aliphatic hydrocarbons, methane and LPG, diesel oil and kerosene, alcohols and glycols, vegetal and animal fats, and hot water up to 100 °C.

-

100% PVC foam product used in various sectors like thermal and acoustic insulation, the automotive industry, promotional material, construction industry and industry in general, and coming in three different qualities;

open cell for a quick return after compression

closed cell for a slow return after compression

rigid (open cell) -

Acoustic insulators are manufactured taking into account effective usage requirements. Multi-layer soundproofing material made with the lamination of smooth open cell polyurethane foam, alternative masses to lead and polyethylene. They are suitable for partition walls, floors, soundproof booths, wastewater, recording studios and the industrial sector. They are available in various combinations; adhesives can be supplied as well as custom designed die-cuts.

-

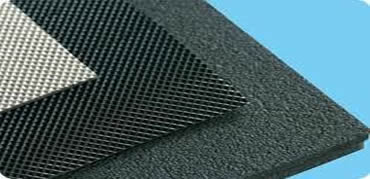

All products can be supplied with various kinds of self-adhesives; the foamed products can be laminated with various films or fabrics according to the customer's requirements. Moreover, the polyethylene foams can be supplied with the embossing shown in the photo on the side.